-

Sewerage Facts

Sewage • Sewage Characteristics • Sewage Treatment Objectives • Sewage Treatment Methods • Sewage Treatment System • The Evolution Of Sewage Treatment Sewage Treatment Plant • Package Plants • Combined Process • Imhoff Tanks • Oxidation Pond Effluent Standards Individual Septic Tanks Population Equivalents Water Cycle Confined Space Ammonia Green Technology Lighter Side

Sewerage Facts

Sewage • Sewage Characteristics • Sewage Treatment Objectives • Sewage Treatment Methods • Sewage Treatment System • The Evolution Of Sewage Treatment Sewage Treatment Plant • Package Plants • Combined Process • Imhoff Tanks • Oxidation Pond Effluent Standards Individual Septic Tanks Population Equivalents Water Cycle Confined Space Ammonia Green Technology Lighter Side - Technical Resources Center

-

INDAH WATER RESEARCH CENTRE

INDAH WATER RESEARCH CENTRE

Package Plants | Aerated Lagoons | Extended Aeration Systems | Oxidation Ditch | Rotating Biological Contractors | High Rate Trickling Filter

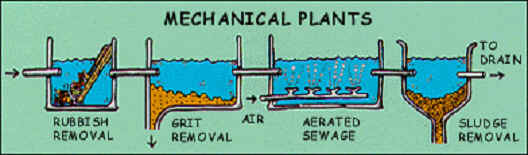

Package/Mechanical Sewage Treatment Plants

Commercially available prefabricated treatment plants known as "package plants" are often used to serve small communities up to population equivalent (PE) of 5,000.

Package plants require little design work and can be installed quickly although they require the same operational and maintenance care as conventional treatment plants. Claims that package plants produce no sludge is incorrect.

Care must be taken in using package plants where large variations in flow (hydraulic shock are experienced), in addition adequate provision must be made for sludge removal, scum and grease removal and the proper control of air supply.

The most common types of package plants use Extended Aeration, Contact Stabilisation, Bio-Filter, Sequenced Batch Reactors and Rotating Biological Contactor processes.

There are now a large number of package plants in the market using a variety of equipment. Uncontrolled selection of plants can lead to problems with operational knowledge and supply of spare parts. Hence, some form of regulation for the use of these plants will be employed to ensure overall industry efficiency.

Further, market forces have driven the manufactures to make optimistic claims for the treatment capacity of small package plants, leading to plants designed in the high rate activated sludge mode in order to reduce the capital cost of construction. This often leads to high operational, maintenance and operator costs due to the need for high operator involvement to keep the plants running within the design parameters.

- CUSTOMER : Please CLICK HERE to see how we handle your personal data

- Click CUSTOMER tab for more info on charges, services, check your account balance & statement of account request

- Click DEVELOPER tab for certifying agency offices, check submission status & get sewerage work-related forms

- Click CONTRACTOR tab for contractor & supplier online registration and IWK Technical Training Centre

- Your feedback is important to us. Please do not hesitate to contact us with your constructive comments.